FARO and TeZet Partner to Provide Leading Tube Measurement Solution in Europe7/24/2008 5:56:00 PMCoventry, UK/24th July 2008 – FARO, the leading provider of portable 3D measurement devices and TeZet, the Swiss-based tube measurement software specialist, have entered into a new European technology and marketing agreement. The agreement marks a milestone for both organisations in their joint effort of providing innovative solutions for tube measurement. Under this new agreement, TeZet’s tube specialised software solution TeZetCAD, will be integrated into the leading portable devices for 3D measurement - FARO ScanArm and FaroArm. Available immediately in Europe, progressive companies such as automotive supplier Automotive Components Penzberg GmbH (ACP) will be able to take advantage of the benefits of the partnership straight away.

“As a supplier of exhaust pipes for construction vehicles, we are very interested in this new solution, particularly because of the level of data quality for bending pipes with a circumference of 150mm and more,” said Georg Baur, divisional head at ACP. “We can now use laser scanners to measure reproducibility and quality control for freeform bent tubes. FARO’s laser arm equipped with TeZetCAD software allows us to easily generate a tube design in a CAD environment.” This new joint solution will be available to customers in all major industries for the measurement and correction of tubes of all sizes and forms, including complex geometries of freeform bent tubes. At present, TeZet is the only software globally that can measure and correct freeform bent tubes.

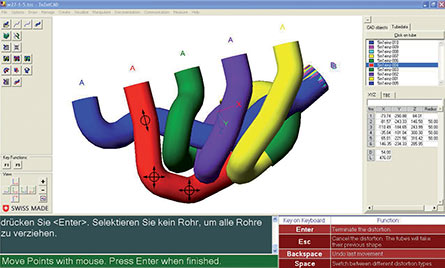

“The agreement with TeZet is very important to us because it allows us to expand our reach into the emerging tube measurement market,” said David Homewood, Area Vice President of Sales for the UK, France and Distribution. “The new partnership will benefit customers who haven’t yet had access to high quality portable laser measurement technology.” The innovative element of the agreement is the ability to measure freeform bent tubes with the FARO Laser ScanArm so that tube benders can actually bend tubes by extracting them graphically from CAD drawings. Until now, the only method that allowed measurement of the reproducibility and quality control for freeform bent tubes was traditional laser scanning. Users need to collect points and convert the point cloud into polygons or nurbs to generate a tube design on the screen without having any tube data, which is a cumbersome and time consuming process. TeZet offers a software module for FARO ScanArms that allows automatic calculation of tube data during the scanning procedure. The user no longer needs to use the complex and lengthy method of converting millions of points in order to extract the tube coordinate and bending data necessary for masterpiece inspection and comparison within the production procedure. “Typical for a Swiss-based company, our mission is to offer precision, quality, software reliability and maximum service,” said Klaus Leistritz, CEO of TeZet. “With FARO we have found a technology partner that helps us to deliver solutions for measuring and automatic generation of the most complicated tube geometries in a user-friendly, menu-guided mode.”

|